Location

Mount Vernon, WA 98274

Location

Mount Vernon, WA 98274

This space explores the craft of computer‑controlled machining, where digital instructions direct tools to cut, carve, and refine raw material into purposeful form. CNC machining blends tradition with technology: the steady rhythm of milling, routing, and turning is amplified by the accuracy of automation. It is a practice that honors both the maker’s vision and the machine’s discipline—revealing designs through subtraction, repetition, and exactitude. Here, we reflect on the quiet partnership between human imagination and mechanical precision, and the enduring beauty of objects shaped by code.

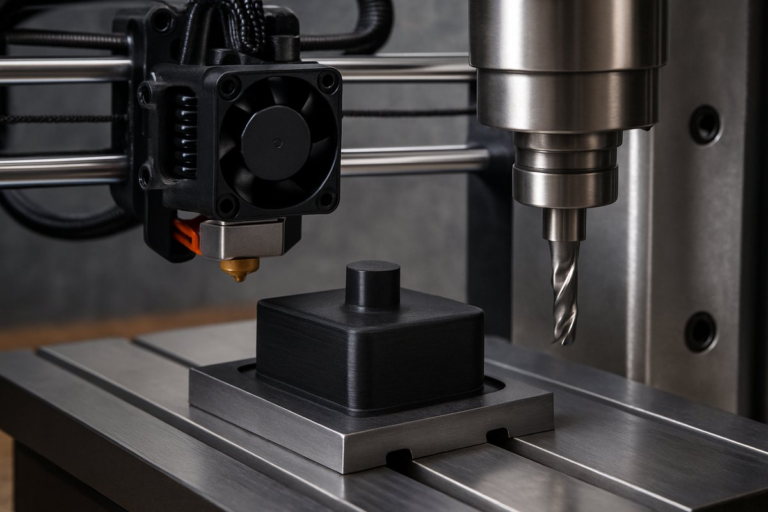

Discover how FDM additive manufacturing can unlock new levels of precision and flexibility in your CNC routing and milling projects. Learn a detailed workflow for designing, printing, and integrating custom jigs and tool holders-plus tips on filament selection and post-processing to ensure rock-solid performance on the machine.

Discover how to integrate desktop FDM 3D printing into your CNC milling setup by creating custom tool holders, quick-change racks, and alignment jigs. This step-by-step guide reviews the fundamentals of filament printing, design strategies, and finishing touches that make your CNC toolbox both nimble and precise.

Explore a hybrid workflow that combines the creative freedom of fused filament fabrication with the precision of CNC milling. This guide walks you through selecting materials, setting up toolpaths, and integrating key components like nozzles and end mills to achieve flawless surface finish and tight tolerances.

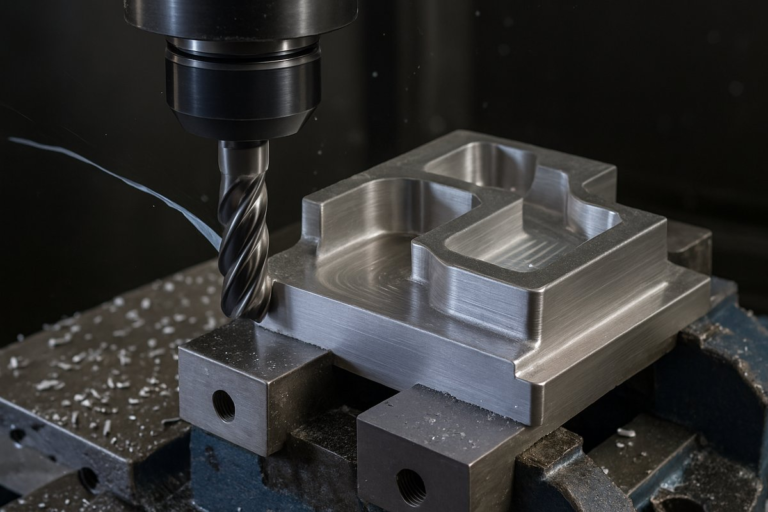

Discover how adaptive clearing revolutionizes CNC milling by maintaining constant tool engagement, reducing cycle times, and extending tool life. This guide breaks down machine setup, tooling choices, CAM parameters, and finishing strategies so you can implement high-efficiency milling on your next project.

Discover how trochoidal milling can transform your CNC milling projects with smoother cuts, longer tool life, and faster cycle times. This guide breaks down tool selection, CAM settings, machine setup, and troubleshooting to help you harness the power of dynamic toolpaths in aluminum, steel, and more. Give your next part the precision and efficiency edge with these practical tips.