Location

Mount Vernon, WA 98274

Location

Mount Vernon, WA 98274

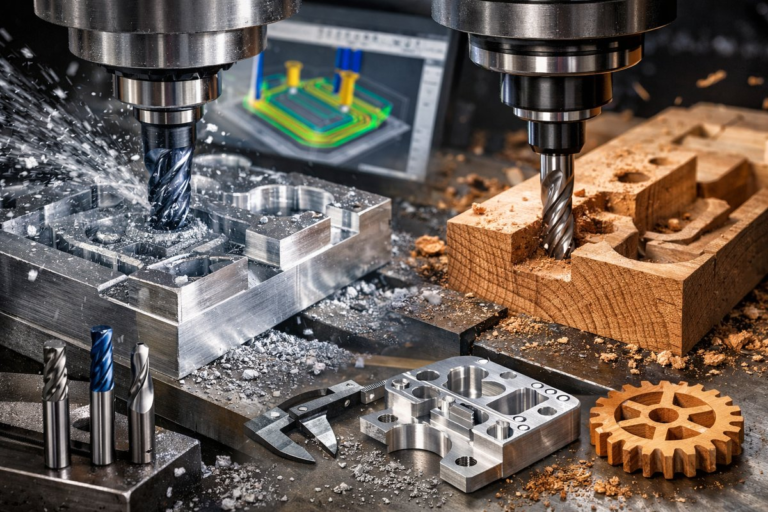

This space reflects on the craft of machining—where precision comes not from adding, but from carefully taking away. Subtractive manufacturing transforms raw blocks of wood, metal, or plastic into purposeful designs through cutting, milling, routing, and turning. It is a practice rooted in tradition yet alive with innovation, balancing strength and delicacy as each pass of the tool uncovers the shape imagined. Here, we honor the quiet discipline of working with resistance, the patience of refinement, and the enduring beauty of objects revealed through subtraction.

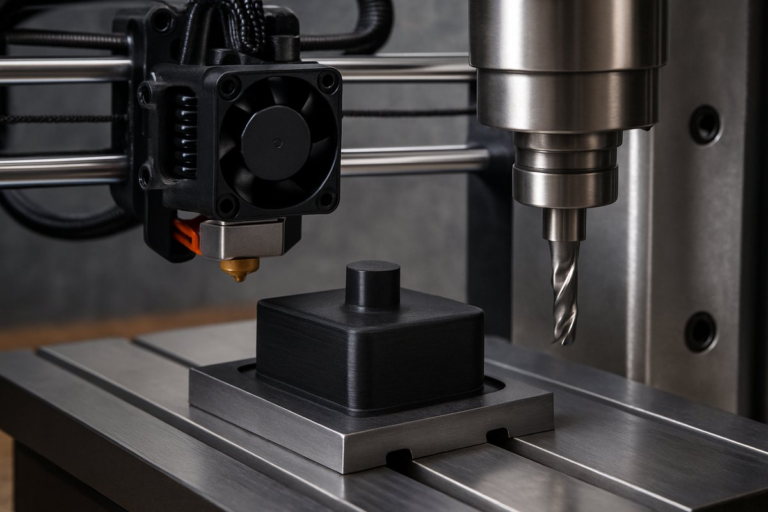

Discover how to combine Fused Filament Fabrication with a desktop CNC router for a one-machine hybrid workflow. This guide dives deep into setting up an extruder on a CNC platform, calibrating axes and extrusion, slicing both additive and subtractive paths, and finishing parts with precision end mills.

Unlock the precision of modern CNC milling by exploring adaptive clearing techniques and the critical role of carbide end mills and high-performance router bits. This guide walks you through material prep, CAM strategies, tool selection, and finishing tips to transform raw blocks of wood or metal into detailed, purposeful designs.

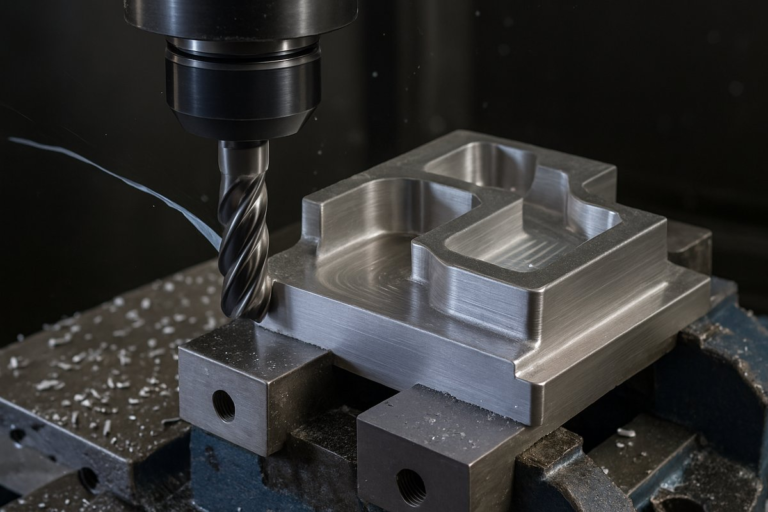

High-efficiency milling (HEM) revolutionizes subtractive manufacturing by balancing shallow radial cuts with deep axial engagement, reducing cycle times and extending tool life. Discover how to select the right end mills, fine-tune feeds and speeds, and program trochoidal toolpaths to achieve exceptional surface finishes and productivity on your CNC machine.

Discover how stereolithography (SLA) 3D printing can revolutionize your machining workflow by producing high-resolution patterns and jigs. This detailed guide reviews key resin printing techniques, design tweaks, and essential tooling to help you bridge the gap between additive freedom and subtractive accuracy.

Discover how FDM additive manufacturing can unlock new levels of precision and flexibility in your CNC routing and milling projects. Learn a detailed workflow for designing, printing, and integrating custom jigs and tool holders-plus tips on filament selection and post-processing to ensure rock-solid performance on the machine.

Discover how to integrate desktop FDM 3D printing into your CNC milling setup by creating custom tool holders, quick-change racks, and alignment jigs. This step-by-step guide reviews the fundamentals of filament printing, design strategies, and finishing touches that make your CNC toolbox both nimble and precise.

Explore a hybrid workflow that combines the creative freedom of fused filament fabrication with the precision of CNC milling. This guide walks you through selecting materials, setting up toolpaths, and integrating key components like nozzles and end mills to achieve flawless surface finish and tight tolerances.

Discover how adaptive clearing revolutionizes CNC milling by maintaining constant tool engagement, reducing cycle times, and extending tool life. This guide breaks down machine setup, tooling choices, CAM parameters, and finishing strategies so you can implement high-efficiency milling on your next project.

Discover how trochoidal milling can transform your CNC milling projects with smoother cuts, longer tool life, and faster cycle times. This guide breaks down tool selection, CAM settings, machine setup, and troubleshooting to help you harness the power of dynamic toolpaths in aluminum, steel, and more. Give your next part the precision and efficiency edge with these practical tips.

Subtractive manufacturing-where raw blocks of metal, plastic, or wood are shaped by removing material through milling, cutting, and turning-remains at the forefront of industrial production. Fueled by advances in automation and sustainability initiatives, the sector continues to expand across aerospace, medical, and automotive markets, balancing tradition with digital innovation.